Picosecond laser cuts smartphone glass

Author:

Source:

Release date:

2020-09-10

Smartphones widely adopt touch displays as their user interface. Typically, these touch displays use four layers of glass—each serving a specific purpose: housing the thin-film transistors and liquid crystal materials, enabling touch functionality, and providing a durable tempered-glass cover. Meanwhile, advancements in wireless charging and 5G communication technologies have led manufacturers to incorporate glass into smartphone back panels as well, enhancing signal transmission quality—and this shift is directly boosting the display industry's demand for innovative glass materials.

Traditional glass-cutting techniques rely on using diamonds or alloys to create micro-grooves on the glass surface. By applying external force along both sides of these grooves, the glass is stretched in its thickness direction, triggering a longitudinal crack that cleanly separates the material—satisfying the processing needs of conventional glass. However, over the past decade or so, the rapid advancement of the display industry has driven innovation in glass technology, pushing toward lighter, thinner designs with superior durability and resistance to damage. In particular, the widespread adoption of tempered (hardened) glass has narrowed the room for further optimization in traditional cutting methods. As a result, achieving high-precision cuts often requires additional steps like grinding and polishing, which not only increase labor costs but also reduce overall production efficiency. Consequently, the display industry now demands glass-cutting solutions that deliver unmatched precision, efficiency, and minimal internal damage—all critical factors for meeting today’s stringent performance standards.

Glass laser cutting is an easy-to-control, non-contact, low-pollution technology that offers significant convenience to customers. At the same time, it ensures clean edges, excellent verticality, and minimal internal damage even at high-speed cutting rates—making it an emerging solution in the glass-cutting industry. In particular, for high-precision cutting applications, picosecond ultrafast lasers shine thanks to their exceptionally narrow pulse widths. Leveraging their ability to deliver extremely low thermal energy diffusion, these lasers can cleanly sever materials before heat has a chance to spread into surrounding areas, delivering outstanding results when cutting brittle materials.

Basic Processing Principles

The laser cutting effect is related to the material's absorption depth at a given wavelength, which is categorized into surface absorption and bulk absorption. In the absorption spectrum of the fourth-generation Corning Gorilla Glass shown in Figure 1, the transmittance for 1064 nm light exceeds 92.1%. Therefore, when using picosecond ultrafast lasers to cut aluminosilicate glass, it is essential to leverage the material's bulk absorption properties.

At the same time, glass is a wide-bandgap dielectric material, and ultrafast lasers possess the unique ability to induce multi-photon absorption within it. As shown in Figure 2, conventional optical absorption occurs when a single photon carries energy exceeding the material’s bandgap, enabling the material to absorb the photon and subsequently excite electrons into a valence-to-conduction-band transition. However, ultrafast lasers deliver extremely high peak power densities, allowing multi-photon absorption even when individual photon energies fall below the material’s bandgap. Specifically, picosecond ultrafast laser pulses inject photons into the material, triggering multi-photon absorption that generates conduction-band electrons. These high-energy electrons then emit phonons as they move through the material, transferring the absorbed energy to the crystal lattice. This energy deposition ultimately leads to localized melting or mechanical damage in the material, enabling precise, high-quality microfabrication processes.

Ultrafast lasers, when focused through a lens, produce ultrashort beams on the micrometer scale with extremely high peak power densities. As shown in Figure 3, when the beam interacts with glass material, the intensity at the beam’s center is lower than at its edges. This results in a greater change in the refractive index at the material’s center compared to its periphery, causing the central portion of the beam to propagate more slowly than the outer regions. Consequently, the beam exhibits a nonlinear optical Kerr effect, triggering self-focusing as the power density continues to rise—until, at a certain threshold, low-density plasma begins to form within the material, reducing the refractive index at the beam’s center and ultimately leading to beam defocusing. In practical glass cutting applications, optimizing the focusing system and adjusting the focal length allows for a repeatable cycle of focusing and defocusing, enabling the consistent creation of stable laser-induced perforations.

Traditional ultrafast laser cutting uses galvanometers to precisely control the laser beam, melting, vaporizing, or inducing thermal stress to cut materials. For thicker glass substrates, this method often incorporates Z-axis lifting and layer-by-layer cutting techniques. Currently, wire-drawing cutting has emerged as a viable process, with the laser industry already offering mature solutions that have been widely adopted across the display sector. As shown in Figure 4, when an ultrafast laser beam propagates through glass, it simultaneously experiences both Kerr self-focusing and plasma defocusing effects. Thanks to the dynamic balance between these two phenomena, the beam can maintain stable propagation over long distances, creating micron-scale "wire-like" holes within the material. These micro-wire structures can extend several millimeters deep into the glass. To achieve uniform spacing among these wire-like holes, a linear motor precisely controls the movement of the glass substrate relative to the laser beam. By optimizing the pitch between the holes, researchers can induce closely spaced microcracks running along the diameter of the glass. Once these microcracks are established, applying external force concentrates stress at their tips, causing the glass to fracture cleanly along the predefined crack lines—thus achieving precise cutting.

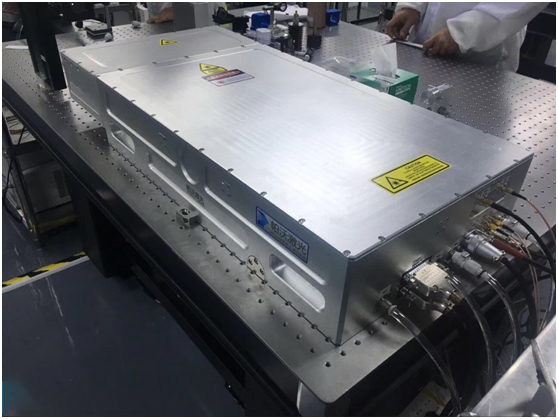

The fourth-generation Corning Gorilla Glass, made of aluminosilicate glass, boasts a thickness of 0.9 mm, a density of 2.42 g/cm³, and a Vickers hardness of 596 kgf/mm². Its fracture toughness reaches an impressive 0.67 MPa·m⁰·⁵. As shown in Figure 5, the system employs a 30 W infrared picosecond laser, featuring a master oscillator power amplifier architecture that delivers high-energy laser pulses with pulse widths below 13 ps. Additionally, the optimized Burst Mode functionality enables precise pulse-string editing, offering greater flexibility for a wider range of processing applications.

Related News

2025/10/23

2024/09/04

2024/08/28

2024/08/21